2014-12-05 - universal filament spool holder

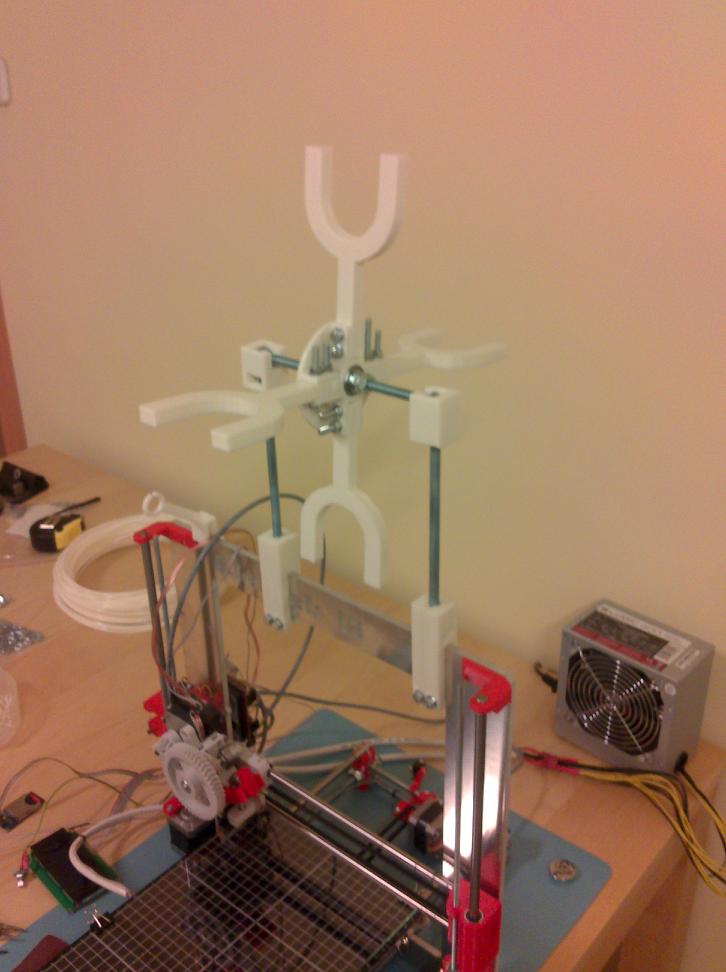

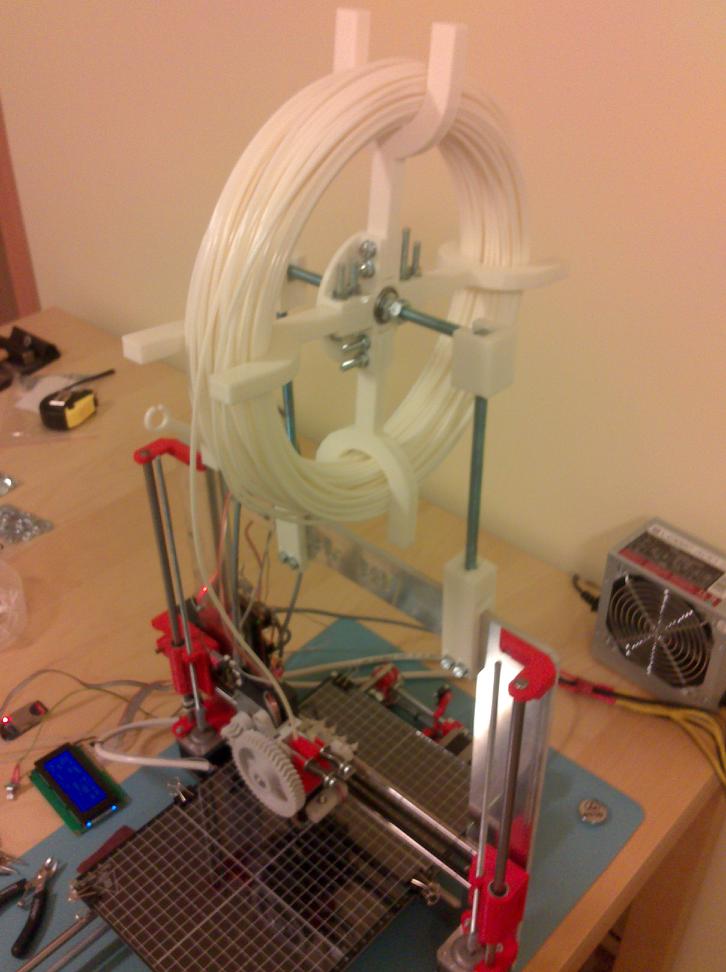

most of my first 3d-prints were add-ons to the printer itself. after doing first two prints i've realized i need a reasonable filament holder. there were many projects to choose from. i've decided to do a clone of filament holder for prusa i3 project. i've modified forks a bit and printed it out. it looks more less like this:

as Tanenbaum once said:

the good things about standards is that there are so many of them to choose from.

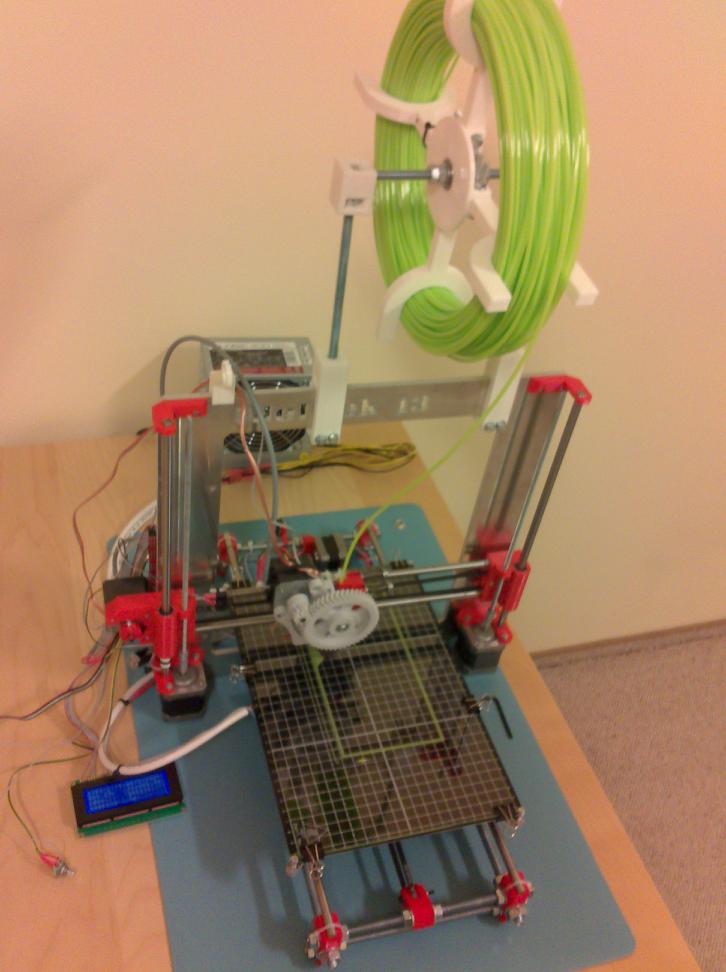

as you might noticed it works nice for filament that comes in without a spool (quite common in poland). however when filament comes already on a spool, why to re-roll it onto a different spool? filament is far from being elastic, thus it is a pain to do. i've decided to create a new filament spool holder. learned on the “standards” experience i've immediately decided to make new holder universal, so that different spools' internal diameters will be accepted. i've also wanted to reuse as much of currently existing holder as possible.

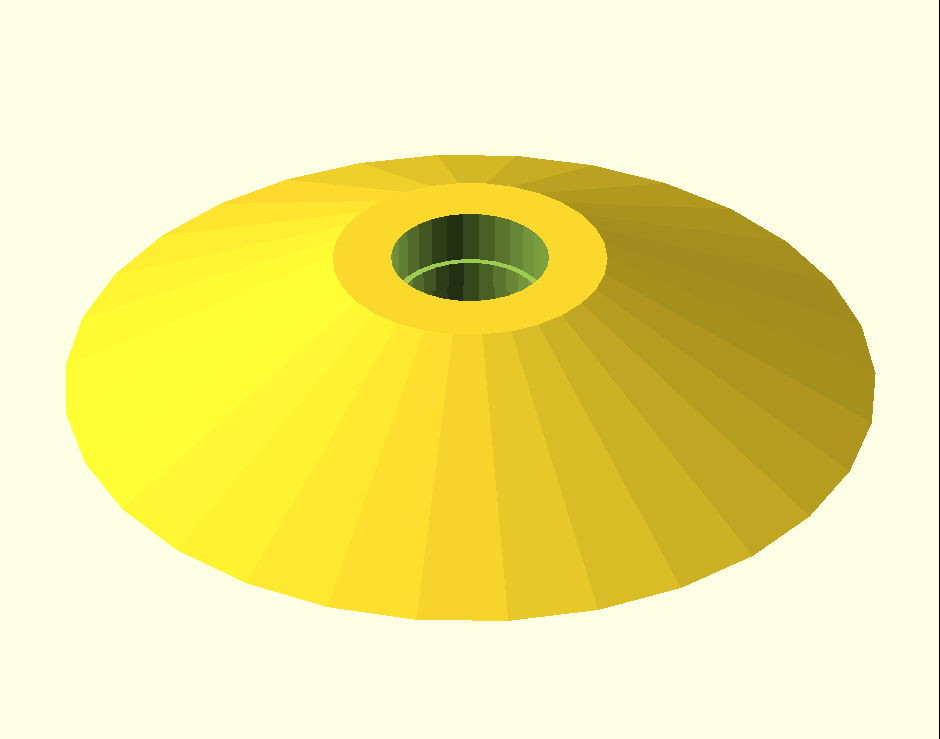

the idea was to print two cons, put them on bearings and mount on top of an existing holder parts. this way only a main axis need to be replaced, to change filament. cones are wide, but low, so that minimal space is required for them. each one has two bearings inside. cone looks like this:

after mounting two bearings on each cone, and screwing it all together on a rod, it looks like this:

cones are hold by double screws each, on one end, and keep the spool in place on the other. this way spool rotates freely on a rod and is easy to unmount. as a free bonus, when printed vertically, cones are not perfectly flat. normally this is a bad thing (does not look that nice), but here it actually makes it easier to mount spool on. :) also by keeping cones short, there is a lot of room inside the spool mounting hole, so parts of filament, used as a hold up for the beginning of the spool do not interfere with rotation.