2012.03.09 - tin whiskers

yesterday i had an interesting talk with wojek, regarding RoHS. looks like proud ideas appear to have a second end, after all. it is a common knowledge, that addition of a lead to a tin makes soldering easier. that's not all, however.

yesterday i had an interesting talk with wojek, regarding RoHS. looks like proud ideas appear to have a second end, after all. it is a common knowledge, that addition of a lead to a tin makes soldering easier. that's not all, however.

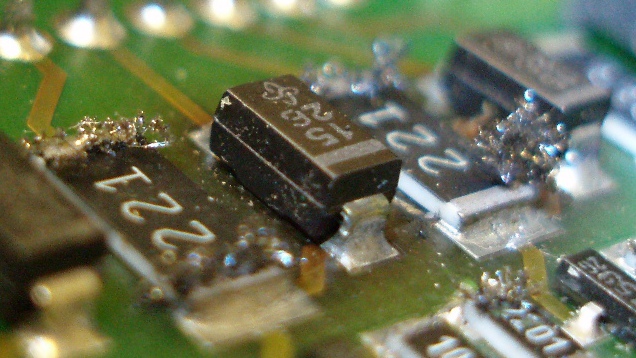

because of the allotropy, “raw” tin changes its chemical and physical properties (including dimensions), and the threshold temperature is around 13 deg C. as one can imagine, it is quite common to see electronic devices in temperatures below and above this temperature. and here is where the whole problem starts. soldering is not only harder to perform, but worst of all – far less durable.

Henning Leidecker et al. from NASA performed studies on the case of broken accelerator pedal's electronics in Toyota's cars. metal whiskers do appear after as little as few years of usage. they are tiny (from 0.1 to 0.01 thickness of human hair), hard to detect, and long enough to make random short-circuits in the electronic devices.

reduction of heavy metals used for the production is a good idea. the thing is – is it worth its price?