2023-11-03 - new hotend cooling

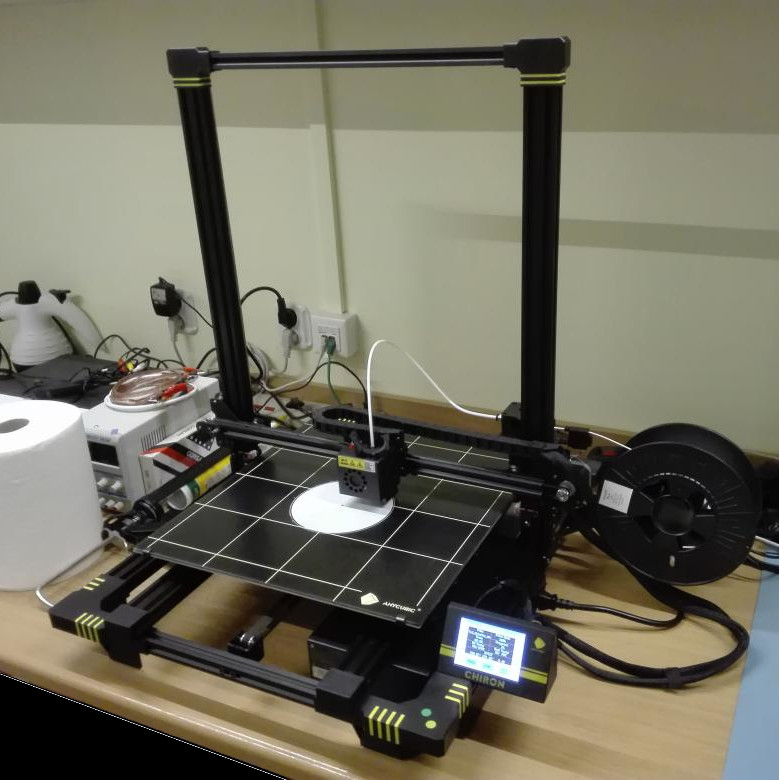

i use anycubic chiron 3D printer.

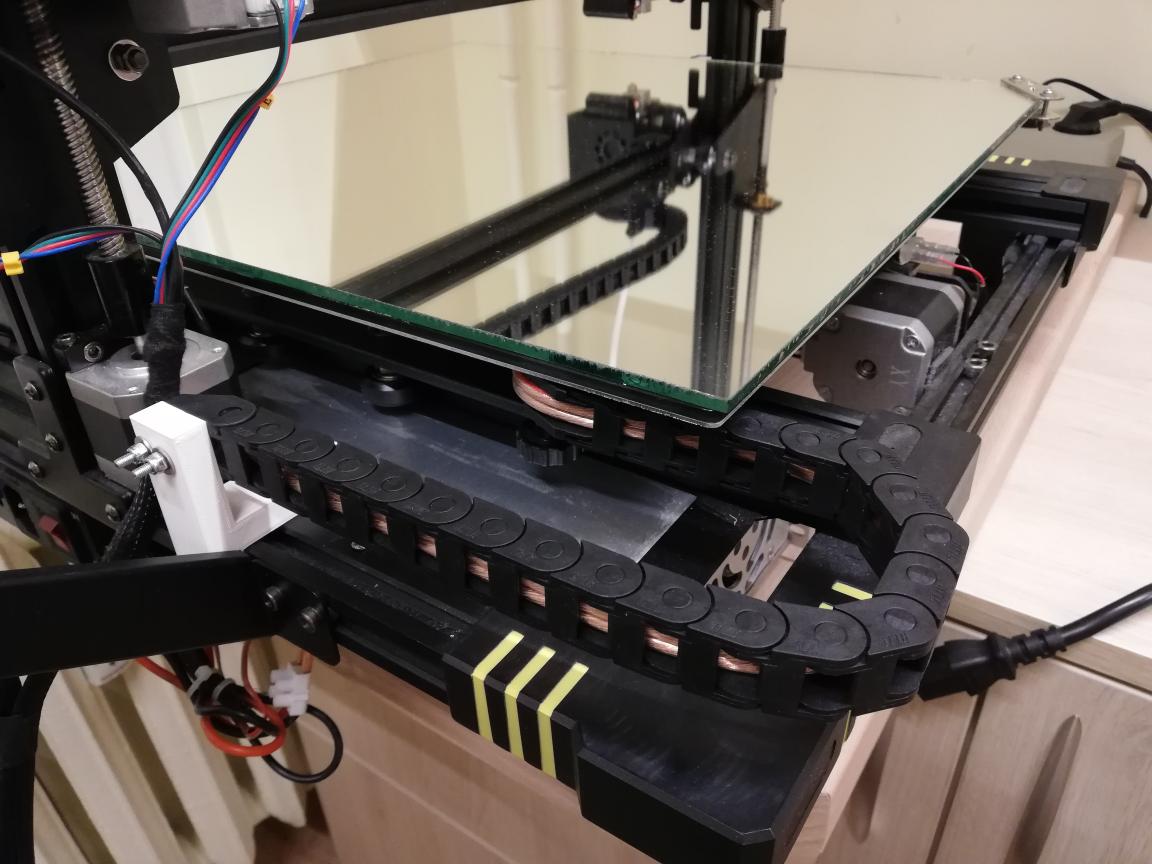

it got modified over time a lot, including: second surface mirror as a printbed and proper cableguides for OY axis.

recently i've decided to change hotend to full-metal one creality spider.

the main criteria for it was for it to be full-metal… and an (almost) drop-in replacement for E3D V5 used by chiron. as you might have guessed by now – the “almost” part became a theme of a last couple days or so… :/ i'll detail the story out in a separate post. for now i'll only focus on a new cooling mechanism.

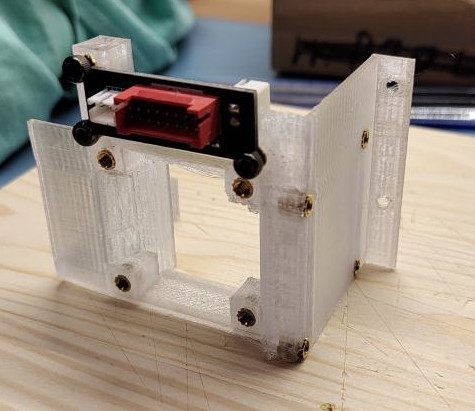

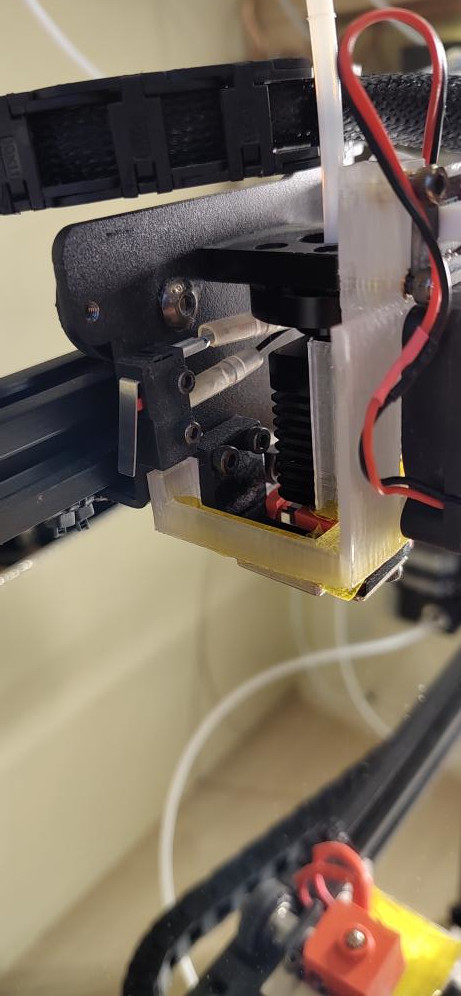

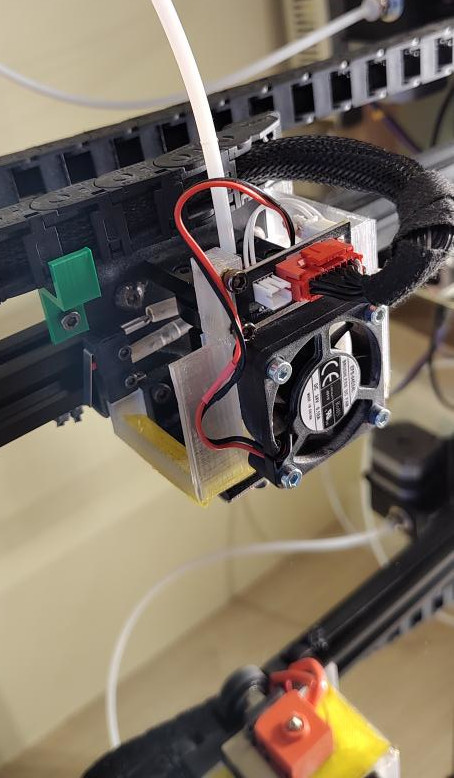

the idea was to make cooling fan blowing directly on the radiator, including proper guides, to make sure air travels pass it's ribs. it took this as an opportunity to also make it as open as possible (both in OSS-spirit and space-wise ;)). last but not least – filament cooling duct was redesigned along the way.

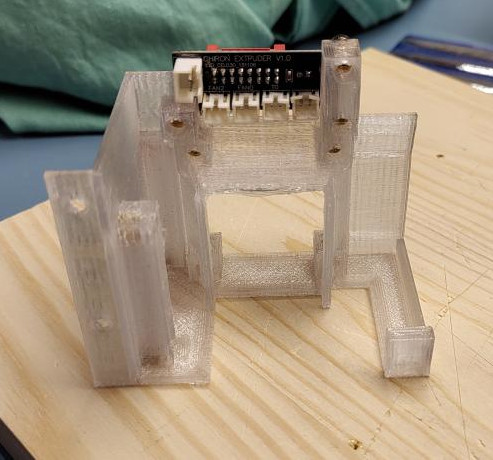

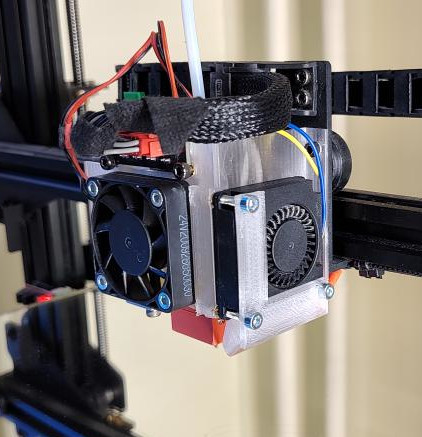

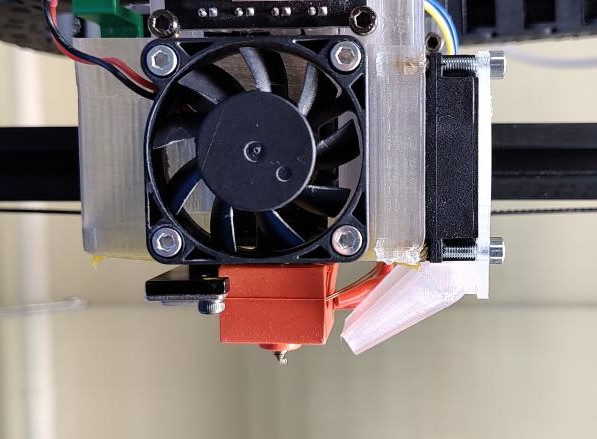

after quite some designing and testing, i've ended up with this.

note that the breakout PCB is now on the front. this makes accessing cables so much easier than before. it also prevents cables from obstructing air flow, as in original design. one thing that could still be adjusted is the height of the PCB – it would make sense to put it 5-10mm higher, to make more space for plugs behind it.

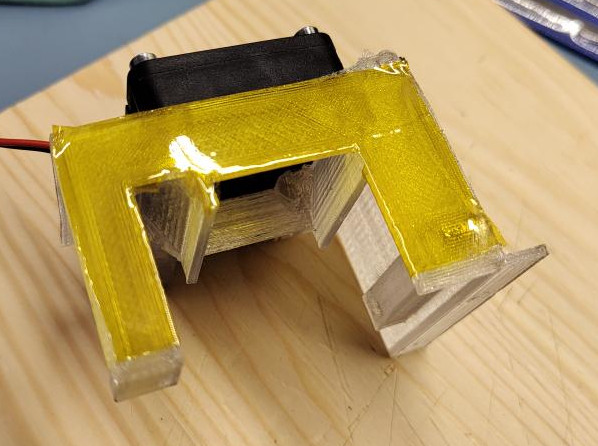

i've printed it out in PET-G and just to be on a safe side decided to cover the bottom part with kapton tape. while it's likely an overkill (it does not touch hotend and is some centimeters away from heated bed at all times), i decided to opted out on a safe side. ;)

after mounting, there's plenty of open space on the left, to make sure warm air can escape. kapton and (fairly closed) bottom parts prevent heat from creeping in from the bottom.

last, but not least – filament cooling fan, with dict pointer slightly below the nozzle.

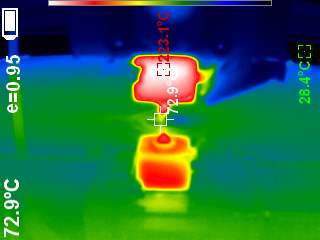

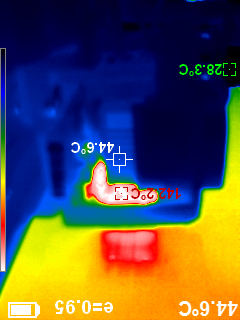

with that, both part cooling and radiator cooling are significantly improved over the stock version. with hotend heated up, it can be seen that bottom of the radiator is around 45 deg.C range, which is totally fine/safe even for low-temperature PLA.

as usual model is available in OpenSCAD format.